IELTS Academic Writing Task 1

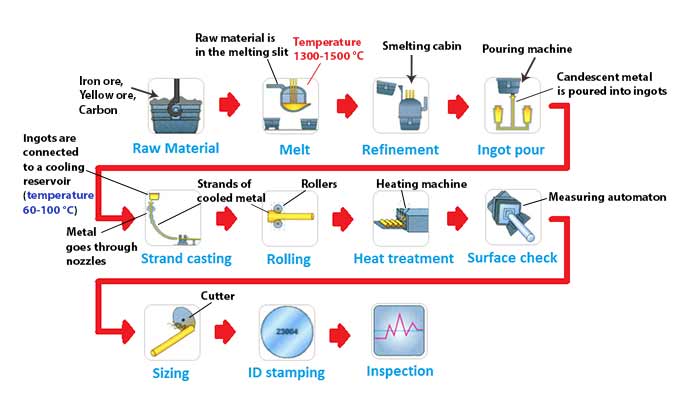

The diagram illustrates how steel rods are manufactured in the furniture industry.

Summarise the information by selecting and reporting the main features and make comparisons where relevant.

Things you should know about Academic Writing Task 1:

- You are asked to describe information presented in graph/ table/ chart/ diagram.

- You have 20 minutes to finish the task and you have to write at least 150 words.

- If you are asked to use the information presented in the graph you must be careful not to copy it.

In Academic Writing task 1, candidates are assessed on their ability to:

- Organise, present and possibly compare data.

- Describe the stages of a process or procedure.

- Describe an object or event or sequence of events.

- Explain how something works.

Model Answer :

The process depicts the various stages of steel rods through which rods are manufactured in the furniture industry.

Overall, the process consists of eleven steps, beginning with the raw material and ending up with the product’s inspection and it is necessary that product cross through each stage otherwise the whole process could be destroyed if a single step is skipped.

To begin with the first stage where, iron ore, yellow ore and carbon are collected as a raw material for steel rods manufacturing. After that, the raw material melt at a temperature in the range of 1300-1500 °C in a melting slit. The melted mass is then shifted to a smelting cabin for refinement. In the next stage, the can descent metal is put in a pouring machine and poured into ingots. Following this, the ingots are connected to a cooling reservoir, where the temperature set in between 60-100 °C. Metal goes through special nozzles and forming strands by cools down the material. Next, the metal strands proceed to rollers that to give them the proper shape. After that, the products put into a heating machine, where they undergo heat treatment. Subsequently, a measuring automaton and check the products surface.

Then, the metal rods are sized by special cutters and the extra portion of the products is cut down to give them actual size. The rods get ID stamping in the next stage. Finally, the products undergo an inspection stage, which completes the whole process.

Read more related post :

- The table below provides information on rental charges and salaries in three areas of London

- The table below shows the salaries of secondary/high school teachers in 2009

- The chart below shows the value of one country’s exports in various categories during 2015 and 2016

- The table below shows the number of medals won by the top ten countries in the London 2012 Olympic games.